See just released high quality promotional videos HERE

Scroll SawsThis site devoted to Hegner Scroll saws is a companion site for The Wood Works Book & Tool Co from where we manage the secure supply and customer support for these machines. Links in this site will take you to The Wood Works site for further information and purchase options. See below for:

INTRODUCTION TO HEGNER SCROLL SAWS A scroll saw is a powered version of a hand fretsaw. A scollsaw has a fine blade which is driven in a vertical reciprocating action in a work table. The work table can be tilted which allows angled cuts. Work is pushed by hand through the blade which is typically extremely fine and allows tightly curved cuts. By pre drilling an access hole in a workpiece then detaching and re-threading the blade through the work, inside cuts are possible. Scroll saws work a wide range of materials, wood, plastics, soft metals, mother of pearl etc  |

|

Hegner scroll saws make little noise, are undoubtedly the safest mechanised wood saw available, have efficient dust collection and can be used in tight spaces which means there is no need to have a large work area. There is a complete library of books and visual media available to offer instruction and project ideas. Hegner scroll saws are widely accepted in schools with thousands in use across Australia. Hegner scroll saws are more than capable of producing commercial scale work such as veranda brackets, toys and the like. Pre-Purchase Checklist You might consider these issues when choosing a scroll saw.

|

Popular Accessories

Quick Release Blade ClampFor the disconnection & reconnection of blades for pierced work. |

|

Work Hold DownThe work hold downs allow the workpiece to be held against the table and prevent chatter. |

|

Lamp BracketFits to the C frame and allows numerous brands of worklamp to be fitted. Versions for all models. |

|

Work LampWe offer an after market angle poise worklamp with an Edison screw cap lamp holder. |

|

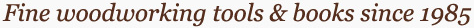

Blade GuardMany educational institutions fit their machines with blade guards. Lifts away for blade change. |

|

FootswitchA footswitch helps with the on/off control of the machine. German made and high quality. |

|

Blade Options

Hegner scroll saws use pinless blades held top and bottom by blade clamps. The advantages of this system are several. The blade is held more firmly in line with the cut, the absence of pins allows very fine pierced work, the clamps retain blade fragments when breakage occurs (unrestrained blade ends can be thrown around when breaking with an eye injury risk), pinless blades are about 25% cheaper and there are numerous patterns available.

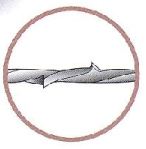

There are standard blades with the teeth all facing in one direction, blades with reverse teeth where both the downcoming and upcoming teeth cut thereby minimising tear out on the workpiece and spiral or twister blades where the teeth are cut in a spiral down the length of the blade allowing workpieces to be cut in any direction without rotating the workpiece.

Standard Tooth Blade |

|

Reverse Tooth Blade |

|

Twister Tooth Blade |

|

OUR BLADE OFFERING

Note: To purchase go to www.thewoodworks.com.au and use the ITEM code in the table in the Home page Product Search search.

In this table ITEM is the purchase code, COUNT is the number of blades which come in either dozen or gross (12 dozen) packs, SIZE is the manufacturer's size code, PINS denotes whether pinless or pinned, KERF is the width of cut the blade makes, WIDTH is the front to back measure of the blade, REV. TEETH is the number of reversed teeth (if applicable), TPI is teeth count per inch, PITCH mm is the distance between teeth in millimetres.

| ITEM | COUNT | SIZE | Pins | LONG | KERF | WIDTH | REV. TEETH | TPI | PITCH mm |

| PEBECO 180 - PINLESS | |||||||||

| L1400 | 1 x doz | #2/0 | no | 130mm | 0.25 | 0.58 | no | 30 | 0.85 |

| L1404 | 1 x doz | #3 | no | 130mm | 0.34 | 0.77 | no | 20 | 1.27 |

| L1406 | 1 x doz | #5 | no | 130mm | 0.39 | 1.03 | no | 17 | 1.54 |

| L1408 | 1 x doz | #7 | no | 130mm | 0.44 | 1.2 | no | 14 | 1.81 |

| L1410 | 1 x doz | #9 | no | 130mm | 0.48 | 1.5 | no | 14 | 1.81 |

| L1413 | 1 x doz | #14 | no | 130mm | 0.55 | 1.9 | no | 10 |

2.54 |

| L1429 | 12 x doz | #2/0 | no | 130mm | 0.25 | 0.58 | no | 30 | 0.85 |

| L1433 | 12 x doz | #3 | no | 130mm | 0.34 | 0.77 | no | 20 | 1.27 |

| L1435 | 12 x doz | #5 | no | 130mm | 0.39 | 1.03 | no | 17 | 1.54 |

| L1437 | 12 x doz | #7 | no | 130mm | 0.44 | 1.2 | no | 14 | 1.81 |

| L1439 | 12 x doz | #9 | no | 130mm | 0.48 | 1.5 | no | 14 | 1.81 |

| L1442 | 12 x doz | #14 | no | 130mm | 0.55 | 1.9 | no | 10 | 2.54 |

| L1443 | 1 Gross of Mixed Sizes, 6 x #7, 6 x #9 | ||||||||

| L1444 | 1 Gross of Mixed Sizes, 1 x #2/0, 2 x #3, 2 x #5, 3 x #7, 3 x #9, 1 x #14 | ||||||||

| TOP CUT #406 - PINLESS | |||||||||

| L1351 | 1 x doz | #2/0 | no | 130mm | 0.21 | 0.68 | 1 in 3 | 38 | 1.5 |

| L1352 | 1 x doz | #1 | no | 130mm | 0.3 | 0.77 | 1 in 3 | 38 | 1.5 |

| L1353 | 1 x doz | #3 | no | 130mm | 0.34 | 0.9 | 1 in 3 | 33 | 1.5 |

| L1354 | 1 x doz | #5 | no | 130mm | 0.38 | 0.93 | 1 in 3 | 33 | 1.5 |

| L1355 | 1 x doz | #7 | no | 130mm | 0.42 | 1.1 | 1 in 3 | 25 | 1 |

| L1356 | 1 x doz | #9 | no | 130mm | 0.46 | 1.35 | 1 in 3 | 20 | 0.8 |

| L1357 | 1 x doz | #12 | no | 130mm | 0.52 | 1.7 | 1 in 3 | 20 | 0.8 |

| L1359 | 12 x doz | #2/0 | no | 130mm | 0.21 | 0.68 | 1 in 3 | 38 | 1.5 |

| L1360 | 12 x doz | #1 | no | 130mm | 0.3 | 0.77 | 1 in 3 | 38 | 1.5 |

| L1361 | 12 x doz | #3 | no | 130mm | 0.34 | 0.9 | 1 in 3 | 33 | 1.5 |

| L1362 | 12 x doz | #5 | no | 130mm | 0.38 | 0.93 | 1 in 3 | 33 | 1.5 |

| L1363 | 12 x doz | #7 | no | 130mm | 0.42 | 1.1 | 1 in 3 |

25 |

1 |

| L1364 | 12 x doz | #9 | no | 130mm | 0.46 | 1.35 | 1 in 3 | 20 | 0.8 |

| L1365 | 12 x doz | #12 | no | 130mm | 0.52 | 1.7 | 1 in 3 | 20 | 0.8 |

| FIX / REVERSE 400/R - PINLESS | |||||||||

| L1371 | 1 x doz | #1 | no | 130mm | 0.3 | 0.77 | 8 | 15 | 1.69 |

| L1373 | 1 x doz | #5 | no | 130mm | 0.38 | 0.93 | 8 | 12 | 2.12 |

| L1374 | 1 x doz | #7 | no | 130mm | 0.42 | 1.1 | 8 | 12 | 2.12 |

| L1375 | 1 x doz | #9 | no | 130mm | 0.46 | 1.35 | 8 | 12 | 2.12 |

| L1376 | 1 x doz | #12 | no | 130mm | 0.52 | 1.7 | 4 | 8 | 3.18 |

| L1391 | 12 x doz | #1 | no | 130mm | 0.3 | 0.77 | 8 | 15 | 1.69 |

| L1393 | 12 x doz | #5 | no | 130mm | 0.38 | 0.93 | 8 | 12 | 2.12 |

| L1394 | 12 x doz | #7 | no | 130mm | 0.42 | 1.1 | 8 | 12 | 2.12 |

| L1395 | 12 x doz | #9 | no | 130mm | 0.46 | 1.35 | 8 | 12 | 2.12 |

| L1396 | 12 x doz | #12 | no | 130mm | 0.52 | 1.7 | 4 | 8 | 3.18 |

| TWISTER - PINLESS | |||||||||

| L1445 | 1 x doz | #1 | no | 130mm | 0.72 | 0.7 | 7 | 38 | 1.5 |

| L1446 | 1 x doz | #3 | no | 130mm | 0.85 | 0.77 | 7 | 33 | 1.5 |

| L1447 | 1 x doz | #5 | no | 130mm | 0.88 | 0.9 | 7 | 33 | 1.5 |

| L1450 |

12 x doz | #1 | no |

130mm |

0.72 | 0.7 | 7 | 38 |

1.5 |

| L1451 |

12 x doz | #3 | no |

130mm |

0.85 | 0.77 |

7 | 33 |

1.5 |

| L1452 |

12 x doz | #5 | no |

130mm |

0.88 | 0.9 |

7 | 33 |

1.5 |

| METAL CUTTING - ANTILOPE - PINLESS | |||||||||

| L1535 |

1 x doz | #1 | no | 130mm |

0.28 | 0.62 | no | 51 | 0.5 |

| L1536 |

1 x doz | #3 | no | 130mm |

0.36 | 0.75 | no | 41 | 0.63 |

| L1537 |

1 x doz | #5 | no | 130mm |

0.4 | 0.85 | no | 33 | 0.77 |

| L1538 |

1 x doz | #7 | no | 130mm |

0.5 | 1.1 | no | 28 | 0.91 |

| L1539 | 1 x doz | #9 | no | 130mm |

0.55 | 1.3 | no | 23 | 1.11 |

| L1550 |

12 x doz | #1 | no |

130mm | 0.28 | 0.62 | no | 51 |

0.5 |

| L1551 |

12 x doz | #3 |

no |

130mm | 0.36 |

0.75 |

no | 41 |

0.63 |

| L1552 |

12 x doz | #5 |

no |

130mm | 0.4 |

0.85 |

no | 33 | 0.77 |

| L1553 |

12 x doz | #7 |

no |

130mm | 0.5 |

1.1 |

no | 28 |

0.91 |

| L1554 |

12 x doz | #9 |

no |

130mm | 0.55 |

1.3 |

no | 23 |

1.11 |